We are pleased to share some exciting updates from our factory recently.

Our Indian customer Ae**** visited us for the on-site Factory Acceptance Test (FAT) and technical training of the Big 96 Carriers Wire Braider for 0.7 mm wire braided hose production.

During the visit, our engineering team demonstrated the full braiding process, machine configuration, and performance testing. Ae*****’s team also received in-depth training on operation, maintenance, and parameter adjustments, ensuring they can achieve stable and highly efficient production once the machine arrives at their facility.

We are honored that Aeroflex placed their trust in us and we are delighted to showcase our manufacturing capability, precision assembly, and strict quality control throughout the machine-building process.

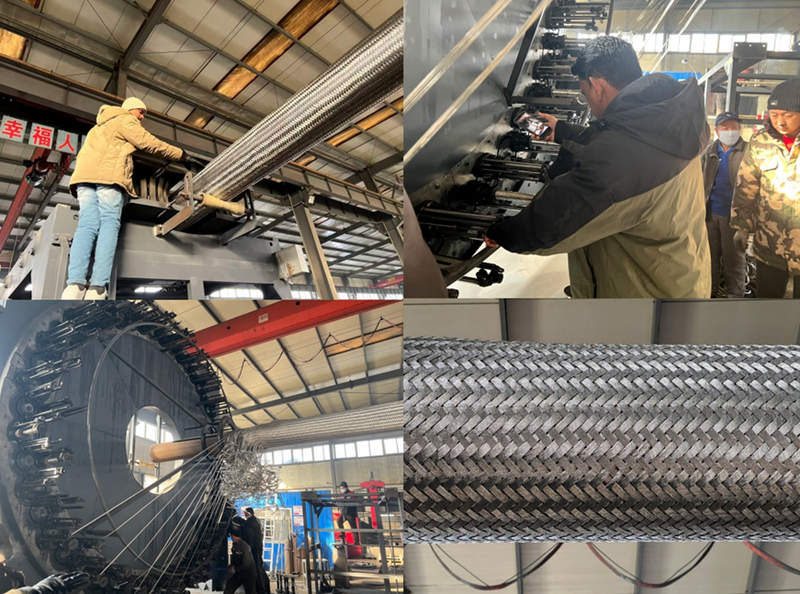

Below are some photos and video highlights from the visit, showing:

- The Big 96 Carriers Wire Braider running at full speed:

- On-site technical training with our engineers

- FAT inspection procedures

We will continue to support Aeroflex throughout shipment, installation, and future technical service to ensure smooth production and long-term performance.\\

Machine running video: https://www.youtube.com/watch?v=g1eFHEndk2U

If you have any inquiries regarding wire braiding machines, hose production lines, or customized equipment, please feel free to contact us at any time. Our team is always ready to assist you.