Description

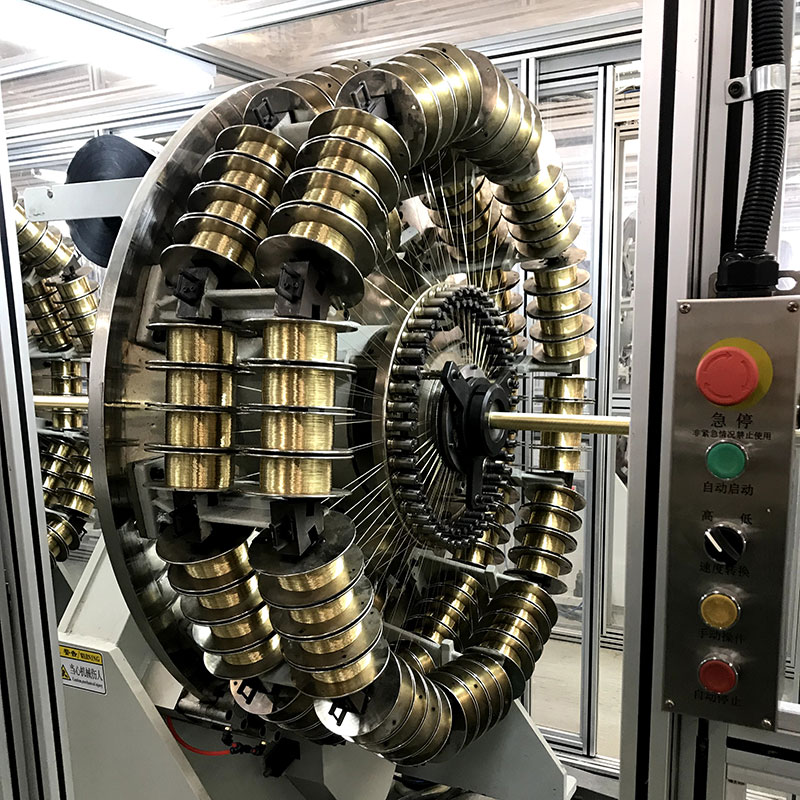

This machine is a new high-speed wire spiraling machine developed, designed, and manufactured by our company. It utilizes the latest on-machine forming technology and a CNC pre-adjustable tensioning force design. Its full CNC control system (PLC + HMI + servo drive) significantly improves winding precision, ensuring high-quality winding at high speeds. Because product stability for wound hoses has long been a major concern in the industry, this winding machine is designed with user-friendly operation in mind. Through independent parting of the winding mold, digital automatic tensioning force control, full servo closed-loop digital control, and digitalized production process management, this machine truly achieves a digitalized production process and product quality model. This eliminates the need for individual employee skills and ensures consistent product quality. By leveraging machine control over human effort, product quality stability is firmly under control.