In the world of manufacturing and industry, precision and efficiency are the keystones of success. Enter wire braiding machines, the unsung heroes behind the scenes, responsible for weaving together the building blocks of countless products. Our company, a leading provider of cutting-edge machinery, is proud to shed light on the versatile and indispensable role played by wire braiding machines.

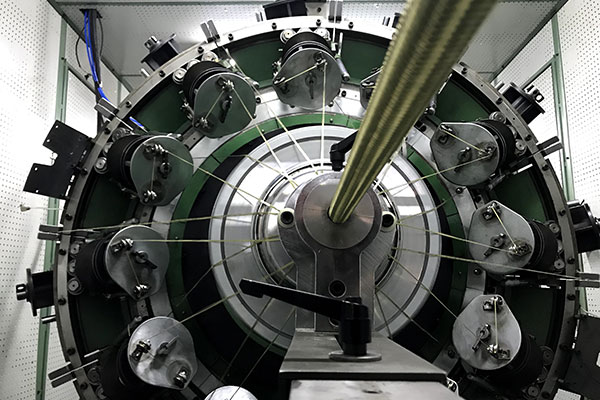

So, what exactly is a wire braiding machine used for? At its core, a wire braiding machine is a mechanical marvel engineered to intertwine wires or threads, creating a sturdy, flexible, and highly functional woven structure. This process is commonly employed in a range of applications, with our machines specializing in the braiding of metal hoses and rubber hoses.

Braiding Metal Hoses: Unleashing Durability and Versatility

Metal hoses are a staple in various industries, and their reliability often hinges on the quality of their construction. Our wire braiding machines excel in this domain, meticulously weaving metal wires around a flexible inner core. The result is a hose with unparalleled strength, capable of withstanding extreme temperatures, high pressures, and corrosive environments.

The applications of metal hoses are diverse and encompass industries such as aerospace, automotive, and petrochemical. From carrying vital fluids to shielding sensitive cables, these hoses serve as lifelines in demanding settings, and the precision of wire braiding ensures they meet the strictest performance standards.

Braiding Rubber Hoses: Enhancing Functionality and Efficiency

Rubber hoses, on the other hand, are the workhorses of fluid transportation systems. They find their place in everything from hydraulic machinery to industrial equipment and automotive engines. Here, our wire braiding machines come into play, reinforcing rubber hoses with precision-engineered wire patterns.

By braiding rubber hoses, we enhance their structural integrity, making them resistant to kinking, crushing, and deformation. This not only prolongs the lifespan of the hoses but also ensures consistent and reliable fluid flow. The automotive industry, in particular, relies heavily on wire-braided rubber hoses to deliver fuel, air, and other essential fluids under varying conditions.

Why Choose Our Wire Braiding Machines?

Our wire braiding machines are the embodiment of quality, precision, and reliability. Engineered with cutting-edge technology and backed by our commitment to excellence, they offer several key advantages:

- Precision: Our machines ensure consistent and uniform braiding, eliminating weak points in the final product.

- Efficiency: High-speed braiding capability enhances productivity, reducing production time and costs.

- Customization: Flexible settings allow for a wide range of braid patterns to meet specific industry needs.

- Durability: Built to last, our machines require minimal maintenance and deliver long-term performance.

In conclusion, wire braiding machines are the unsung heroes behind the scenes, contributing to the strength and reliability of hoses used across industries. Our commitment to delivering top-tier braiding machines ensures that your production processes remain at the forefront of efficiency and quality. For more information on our wire braiding machines, please visit www.braiderchina.com.